How Has Technology Changed Sign Manufacturing?

Share

The world of sign manufacturing has been revolutionized by technology. From design to production, each step has undergone transformative changes that have made the process more efficient and personalized. In this blog, we’ll explore the significant ways technology has impacted sign manufacturing.

Digital Design Technology

Digital design tools have revolutionized how signs are conceptualized. Designers now use computer software to create precise and complex sign designs that were difficult to achieve manually. This software allows for intricate detailing and flexibility, enabling users to experiment with various styles and layouts before settling on a final design. With integrated features that simulate real-world environments, clients can visualize what their signage will look like in situ, eliminating guesswork and ensuring satisfaction.

Furthermore, digital technology has made it easier to incorporate customer feedback into the design process. Instead of multiple iterations, designers can make quick adjustments, and clients can see changes in real-time. Not only does this improve communication between designers and clients, but it also significantly shortens the design cycle, making projects more cost-effective and faster to complete. This capability is empowering businesses to maintain a competitive edge by bringing their creative visions to life more accurately and swiftly.

Automation and Production Efficiency

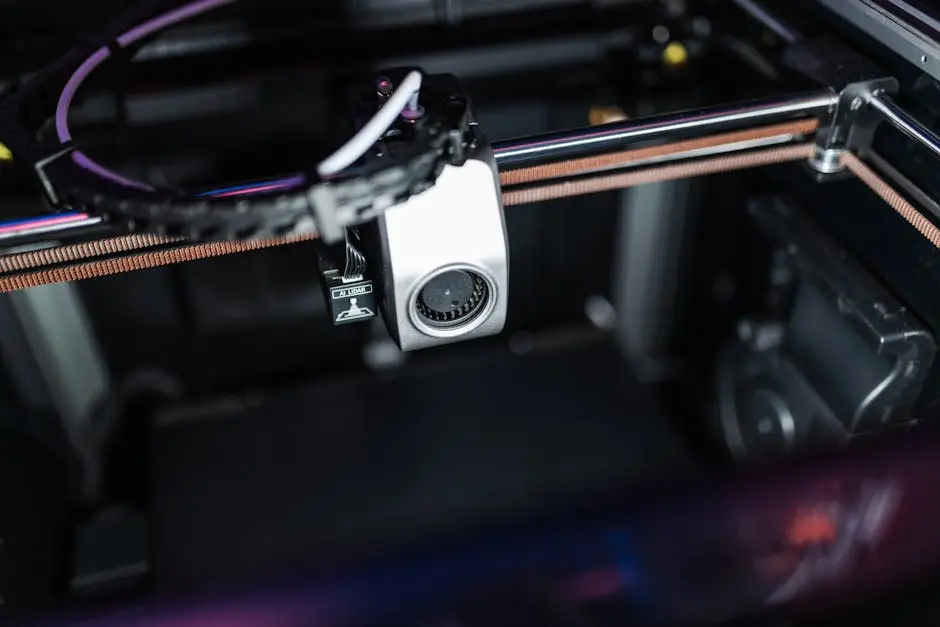

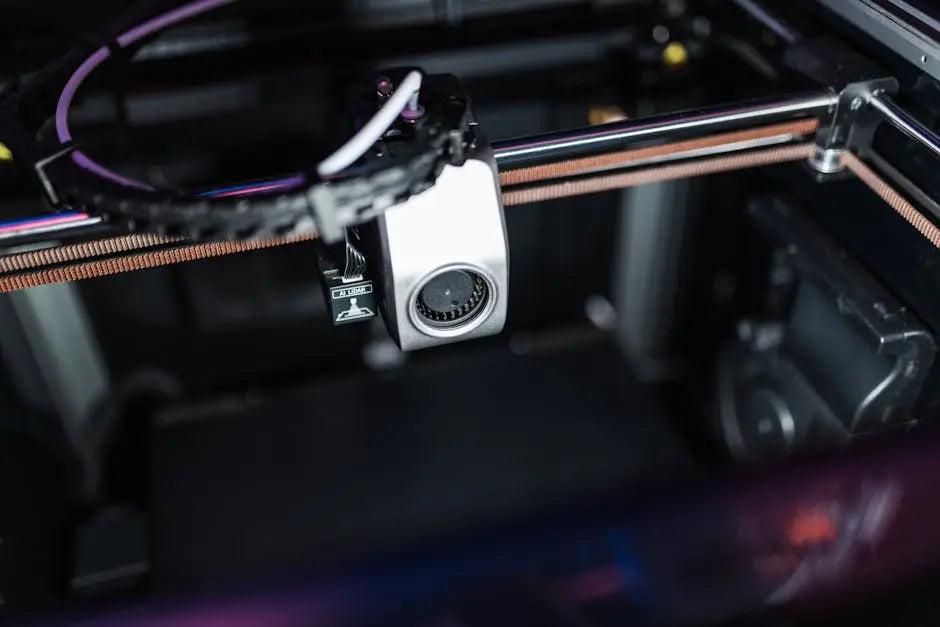

Automation has streamlined the production process, reducing human error and increasing manufacturing speed. Machines handle tasks such as cutting, engraving, and assembly with precision. By minimizing manual intervention, manufacturers can ensure that each sign is consistent in quality and measurements, which is crucial for large-scale projects. This consistency can enhance brand reliability and customer trust.

Additionally, automated systems can work around the clock without fatigue, vastly improving production timelines. These systems, combined with modern printing methods, enable high-volume production without compromising on quality. For businesses that depend on rapid turnaround times, this shift toward automated production processes is a game-changer.

Through the integration of advanced machinery, the sign manufacturing industry has seen a notable reduction in production costs. The initial investment in automation technology often pays off in spades through savings on labor and material wastage. This financial leeway allows companies to allocate resources to other areas like innovation, customer service, or marketing, driving overall growth and competitiveness.

Innovations in Material Use

New materials and techniques have emerged, allowing for more durable and versatile signage. These innovations include weather-resistant materials and eco-friendly options. Manufacturers now have access to substrates that are designed to withstand harsh environmental conditions, extending the longevity of outdoor signs.

The trend towards sustainability is gaining traction with the use of solvent-free inks and recycled materials as highlighted in the modern printing methods observed in today’s industry. This movement not only appeals to the environmentally conscious consumer but also aligns with global needs to reduce waste and the carbon footprint of manufacturing processes. By incorporating these eco-friendly materials, sign manufacturers are contributing to a more sustainable future while still providing high-quality products.

Personalization and Customization

Technology enables greater personalization, allowing businesses to create signs that reflect their brand identity. Customers can choose from diverse options, tailoring signs to their specific needs. This customization ranges from the choice of colors and fonts to the integration of logos and multimedia elements.

The ability to customize signage extends beyond aesthetics—it’s about functionality too. Businesses can incorporate features like QR codes or digital displays to enhance customer engagement directly through their signage. The intersection of modern printing methods with customization capabilities further enhances the interactive potential of signage.

Integration of Smart Technology

Smart technology integration has added another dimension to signs with interactive displays and digital features. Signs are not just informative anymore but also engaging and interactive. They can display real-time data such as weather updates, news feeds, or promotional content, providing dynamic interaction between the sign and the viewer.

Looking ahead, emerging technologies such as AI-driven design tools and augmented reality promise to further redefine how signs are conceptualized and produced. These sign industry innovations have the potential to create more immersive experiences where users can interact with signs in unprecedented ways. By embracing these technologies, the future of sign manufacturing is poised to become not only more engaging but also more aligned with cutting-edge digital trends.

Embracing the Future of Sign Manufacturing

Technology has undeniably transformed sign manufacturing, making it more efficient, affordable, and versatile. As advancements continue, the possibilities for innovations in sign production are endless, setting the stage for even more personalized and diverse signage solutions.